10 Things to Consider When Looking for a Quality Machine Shop

In every industry, manufacturing, or construction, having the right machine is very important. A machine is a considerable investment, so you should choose the right one for your machining needs.

With several machine shops available, choosing the right shop that delivers quality can be an uphill task. You may not know what questions to ask or what to look for in the right machine shop.

If you are looking for a machine shop, here are a few things that you should consider:

1. Support and Quality Services

When looking for a machine shop, you want a partner who will work closely with you so that they can ensure that you are satisfied with their products and services.

Know the shop’s quality policy, their hours of operation, how long they have been in business, and more. The answer to these questions will help you have a slight idea of what partnering with the shop would be like. If they are friendly and willing to answer your questions, you can consider them.

2. Machining Technology

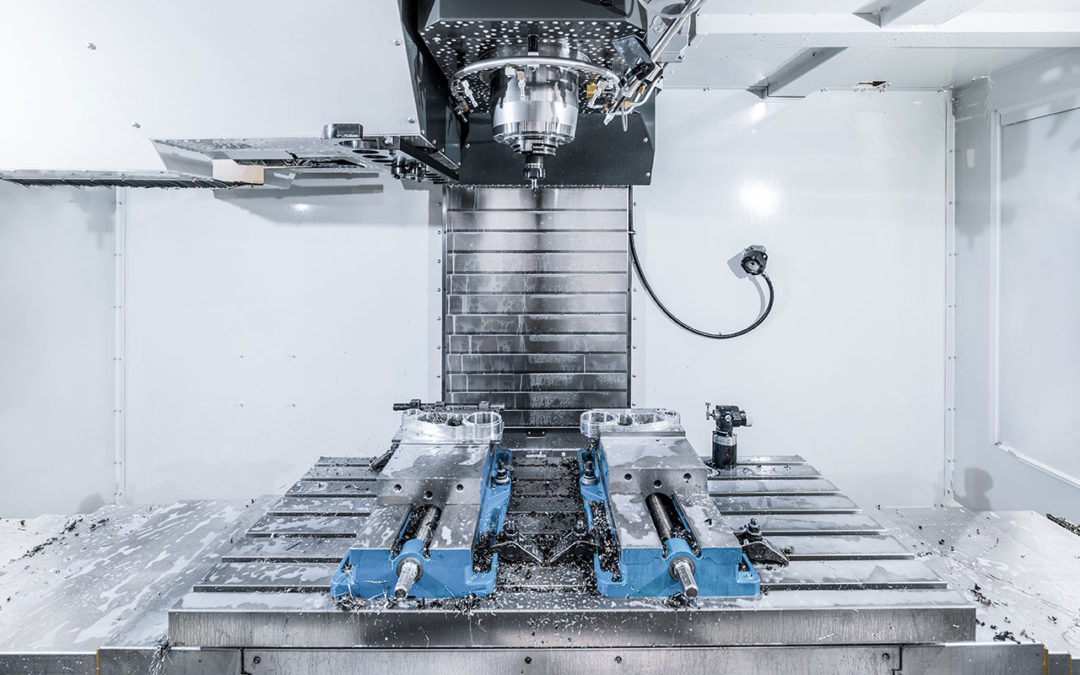

Several principles behind machines have not changed. However, the technology used has changed so much. Technology has come with many benefits, more efficient production, increased capabilities, cost efficiencies, and improved accuracy.

Quality machine shops use the latest technology available to ensure that they offer quality. Your shop should be able to provide the parts that you need efficiently, accurately, and on time. Check if the machine shop has invested in modern technology or still using outdated processes.

3. Capabilities

Before you can even request a machine shop to handle your machining needs, you may want to find out if they can handle your project. Ask to know the type of equipment they have, the skills they possess, and the right tool to mill, drill, turn, and lathe.

Machines, such as CNC machines, have several functions and styles. A shop that uses a broader range of turning machines is able to accommodate different parts sizes. The more the axis that a milling machine has, the more the precision work.

Ensure that the shop is flexible, versatile, and capable of meeting your needs no matter your project’s size.

4. Certification

Depending on your industry, you may already know about ISO 9001 certification, what it means for a business, and what it means for the customer. As much as this certification is voluntary, it goes a long way to dictate how a company operates and how it handles its projects.

The International Organization of Standards (ISO) creates the ISO 9000 family of standards, and among them is the ISO 9001, which is the only certification that a business can hold. It is a mark of quality. It would be best to choose a machine shop that has this certification.

5. Coordinate Measuring Machines (CMM)

When precision is a priority to you, the right machine shop should be equipped with an excellent coordinate measuring machine. This way, they will be able to measure the part against your drawing and capture it precisely as it should be.

CMM will help ensure that your machining needs are fulfilled and a high-quality part is produced.

If you can visit the shop, check out how well they are organized and the kind of measuring machines they have. Do not forget to check if the CMM uses the latest technology.

6. Materials

Different shops have different types of equipment and different areas of expertise. This includes the types of materials that they can work with. You will want to ensure that the shop is able to work with the material that you have.

For example, if your material is fragile or brittles, the machine shop should have experts in wire Electrical Discharge Machining (EDM) services. This will allow them to cut through the delicate material by the use of heat while preventing rust.

7. Quality Control

A company with ISO certification has proven that it is capable of offering high-quality products and services, focusing on customer support, and having a clear communication channel. This and other certifications show that they also have a way of ensuring accuracy through quality control.

8. Customer Reviews

Customers always have something to say, whether positive or negative. Reading a company’s customer reviews will give you an idea of who they are and how they offer their services.

Find out who the shop has worked for before, ask for testimonials, and carefully examine those reviews so that you can have a picture of what you should expect.

9. Future Business Needs

When looking for the right machining partner, you should always try to focus on the big picture instead of a few aspects of a company. Try not to evaluate the shop based on prices alone, but dig a little deeper and look at how they operate from different angles.

10. Previous Work

Quality companies are able to provide potential customers with samples of the work they have done before. If they do not offer the samples upfront, make a request, and see what they can deliver.

Consider These Tips to Choose the Right Machine Shop

A highly versatile machine shop will offer you various machine operations and quality services so that you do not have to look for another shop in the future. Choose a partner who has the right equipment, knowledge, expertise, and is committed to updating their technology.

If you have any machining needs, talk to us here at Manitowoc Tool and Machining. We combine highly efficient equipment with the latest technology to deliver quality parts and services that will exceed your expectations. Having been in business for several years, we have partnered with leading companies, and we stay committed to excellence.

For more information, visit our website and get in touch with us today.