Sep 25, 2023 | MTM News

Employment Info

We are currently hiring Machine Operators for 2nd Shift, 2nd Shift Weekends and 3rd Shift Weekends. We offer a robust, on-site training program. Benefits include: Competitive Wages and Benefits, Temperature controlled facility, Tuition Reimbursement, Robust on-site training program, 401K, Company Paid Life Insurance, Short-Term Disability Benefits and Advancement opportunities!

Please Mail your completed application to:

Attention: Human Resources Managers C/O

Manitowoc Tool and Machining , LLC

4211 Clipper Drive

Manitowoc, WI 54220

or send it by fax to: (920) 682-4299

If you would like to email your resume for a posted job opening please use the email link below the applicable job posting. This will ensure the correct staff member receives your resume. Other resumes being sent or future consideration can be emailed to: humanresources@mantool.com

MANITOWOC TOOL AND MACHINING, LLC is an equal opportunity employer. We consider applicants for all positions without regard to race, color, religion, sex, national origin, age, marital or veteran status, the presence of a non-job-related medical condition or handicap, or any other legally protected status.

Sep 9, 2020 | MTM News

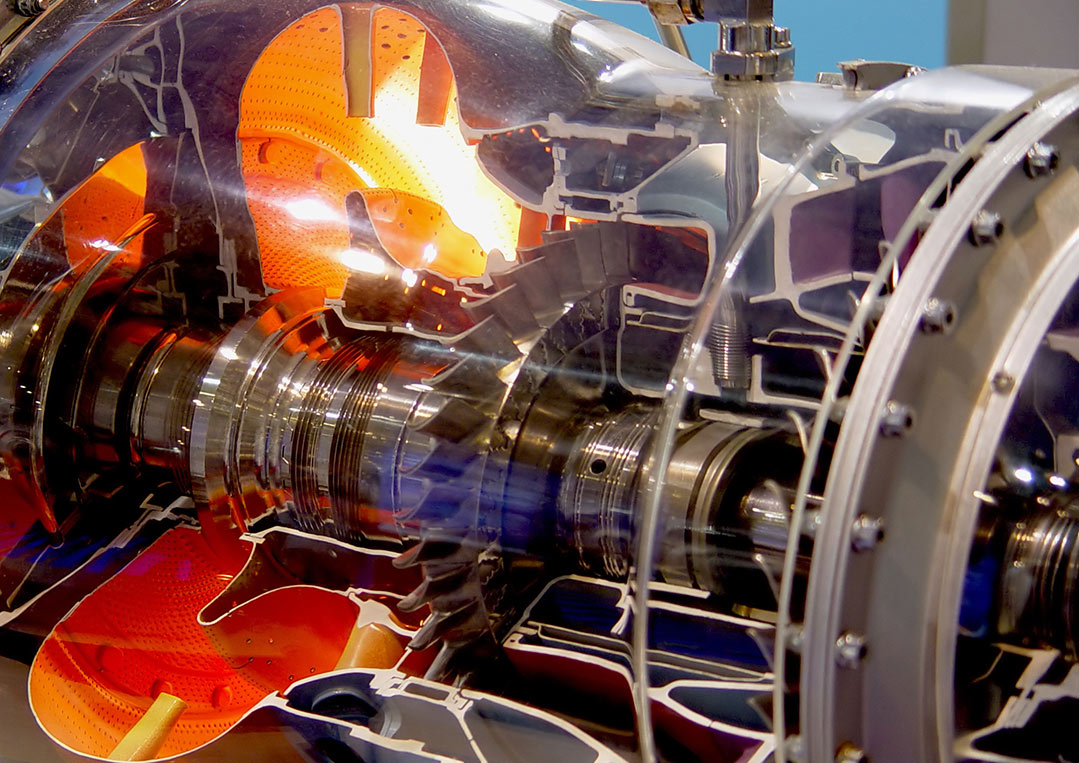

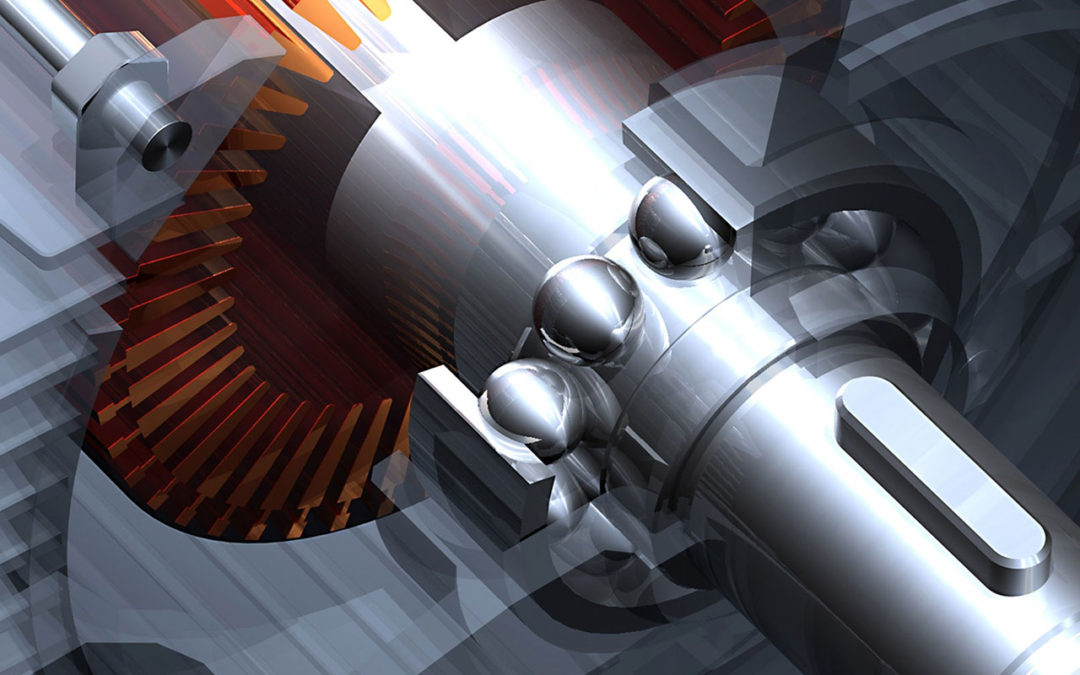

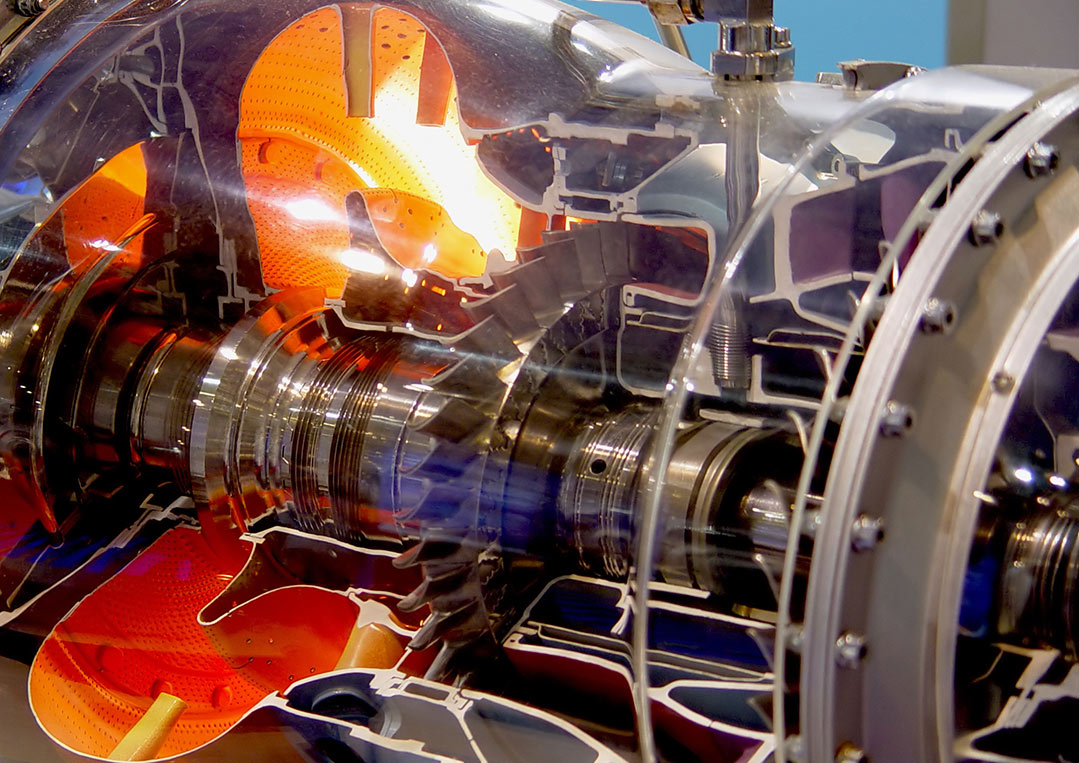

Aerospace Engineering & Machining

When it comes to high-tech vessels like space shuttles, satellites, helicopters and aircraft, utilizing high precision machining and even higher-level project planning is paramount. MTM is devoted to producing precision aerospace components, machined to the highest level and backed by our AS9100 certification.

When it comes to high-tech vessels like space shuttles, satellites, helicopters and aircraft, utilizing high precision machining and even higher-level project planning is paramount. MTM is devoted to producing precision aerospace components, machined to the highest level and backed by our AS9100 certification.

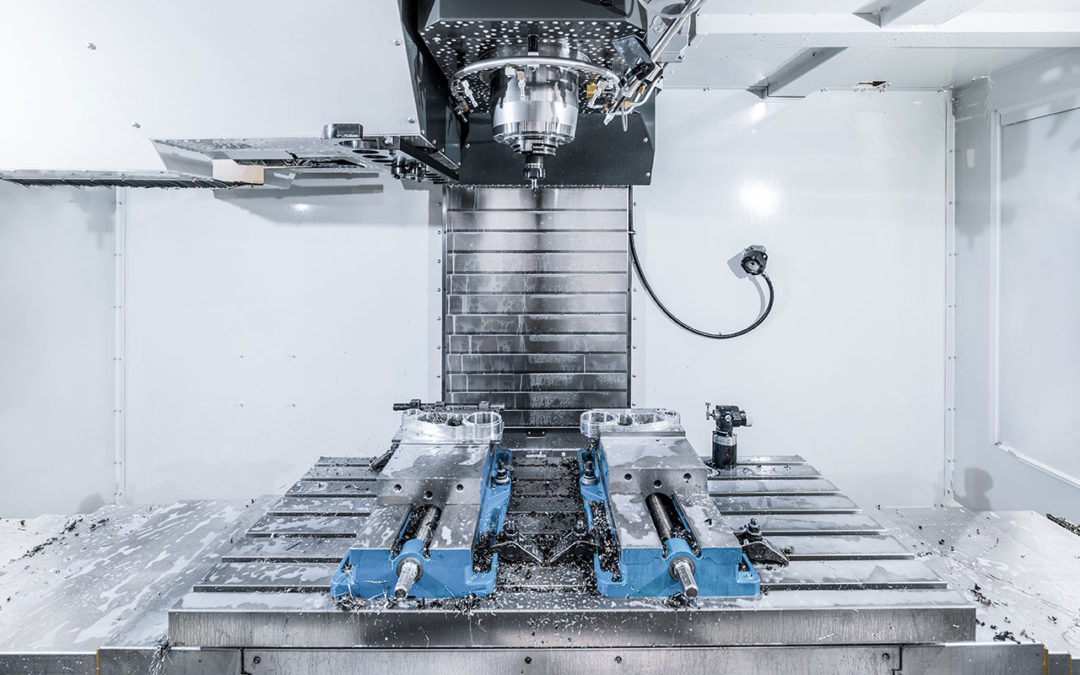

MTM’s engineering team is constantly looking for new ways to improve and enhance the quality of our Aerospace CNC machining practices. AS9100 certified with state of the art 3 and 5 axis CNC Machine centers, along with world class CMM (coordinate measuring machine) equipment, MTM’s customers can rest assured they are getting the best machining services for their high precision parts available. The customer may supply their own castings or rely on us to source them from one of our many reputable foundries.

- Aluminum is a lightweight metal that provides excellent ductility and durability when finished. Because of its corrosion resistance and high electrical conductivity, it’s ideal for a variety of aerospace applications and aerospace parts including housings, electrical connectors, oxygen generation parts, filter bodies, castings, seats, and more.

- Stainless steel resists corrosion and can withstand strong impacts as well as regular wear and tear. Stainless steel can also withstand scratches, extreme temperatures, and low pressures.

- In addition to stainless steel and aluminum, MTM also works with metals including Inconnel, titanium, and high-stress alloys.Manitowoc Tool & Machining can shape these metals into many different components for aerospace applications, such as:

- Housings

- Electrical connectors

- Parts for oxygen generation

- Filter bodies

- Castings

- Seats

- Aerospace & aircraft

Contact one of our project specialists today at: 920-682-8825 or fill out our online Quote Request Today.

Manitowoc Tool & Machining is headquartered in Manitowoc, Wisconsin: aero engineering, aeronautical manufacturing & engineering, aeronautical companies, aeronautical design, aeronautical engineering and astronautical engineering, aeronautical engineering companies, aeronautical engineering near me, and aeronautical manufacturing.

Aug 3, 2020 | MTM News

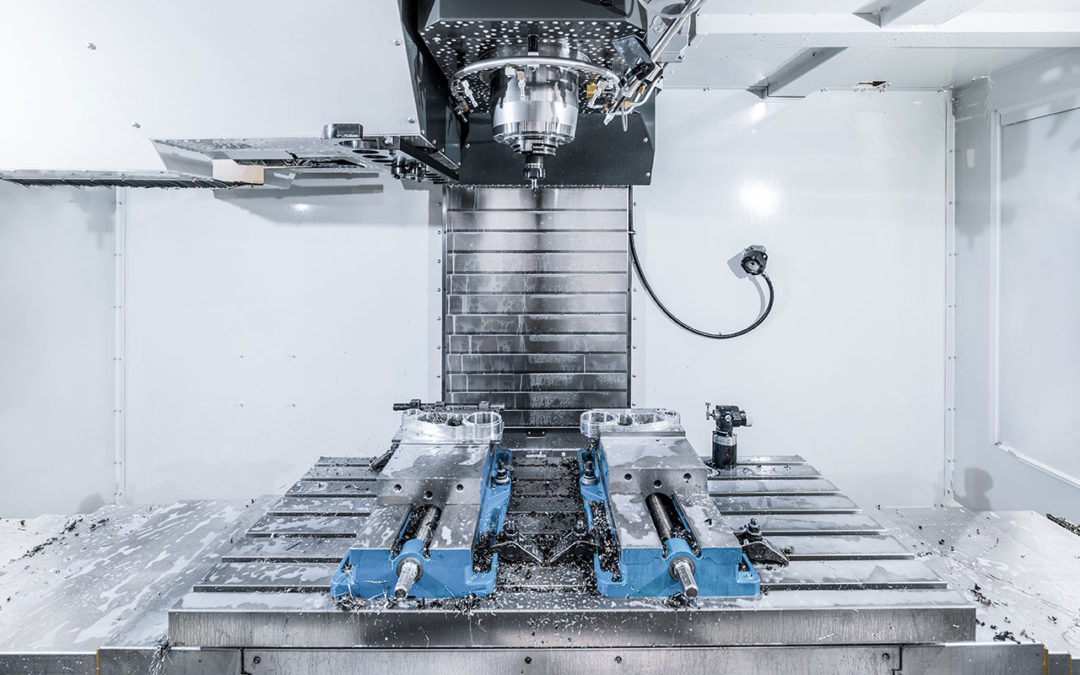

Does your product require parts to be fabricated out of metal? Are you looking to hire a CNC machine shop but don’t know where to start?

It can be a tough task since CNC machining is a highly-skilled industry. Not to mention, there is no shortage of options in today’s marketplace.

How do you know if you’re using the right machine shop for you? We have 5 questions to ask to help you avoid CNC machine shop remorse.

Let’s go over them now.

1. Do They Have Experience?

Like with anything else, you’ll want to make sure the CNC machine shop you’re working with is experienced in their trade. More importantly, you want to make sure the CNC operators have experience manufacturing the components specific to your product or industry.

This type of specialized experience shows that the operators will be able to deliver the parts to your product with the highest industry standards. In addition, it helps you to put your mind at ease knowing whatever is produced by the shop will not only meet the standards of the shop supervisors but your quality control standards as well.

2. What Are People Saying?

Does the shop you’re considering have references or reviews? If you can’t find anything online, don’t be afraid to ask for names and phone numbers of companies they’ve worked with in the past.

It doesn’t hurt to begin your search by asking around. Other businesses within your industry, or maybe other vendors that need a machine shop, could have a hidden gem for you. Referrals can be the best form of advertising, no matter the industry.

3. What Are Their Processes?

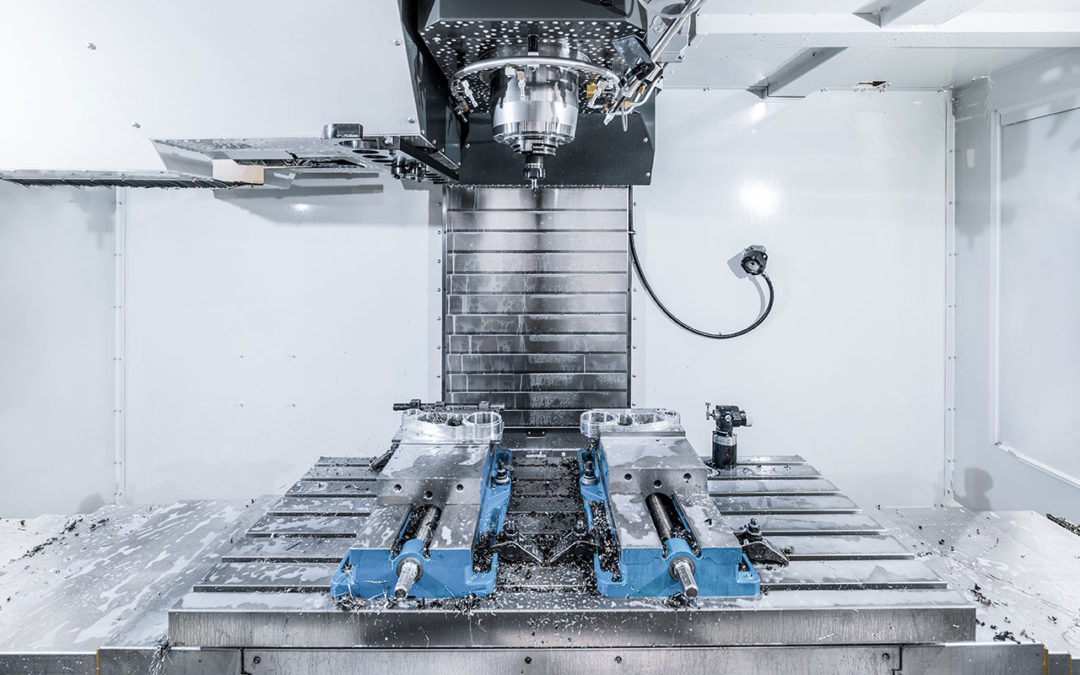

When you want to hire a CNC machine shop, it’s important to have your end goal in mind. Machine shops use different processes depending on the results they’re looking to achieve and the material they’re using. You’ll also want to factor in whether you need a smooth or rough surface for your components.

Any of your desired results could be achieved by a qualified machine shop, but knowing what you want and communicating it to your supplier will go a long way in selecting the right shop.

The shop you’re considering should also have a variety of machines. Some shops, especially ones that are just starting out, may have older equipment. These machines are solid, but you may want to pursue a shop that has newer technology.

All of that depends on the type of materials you need to use, and the precision your components need to have.

4. Is Their Work High Quality And Consistent?

This is where your list of references will come in handy. Call them and ask them how the quality of the shop’s work was. Was it to their Quality Control standards, or did they keep having to get parts re-machined?

Are they capable of handling the type of work you require? Can they handle the volume you require? Do they offer mass-production or are they primarily a custom order shop?

You’ll also want to make sure that they can provide you with consistent work. Ask past customers if work was delivered on-time, and was the work the same every time. This is especially true if you’re dealing with a component of a bigger product.

That particular part should look, feel, and fit into the larger product the same way every time.

Another thing to look for when searching for a machine shop is an ISO certification. This can weed out a lot of shops right off the bat. The ISO certification will ensure you’re dealing with a shop that adheres to the utmost quality standards and is equipped to give you the machined components you are looking for.

5. How Is Their Customer Service?

Ask the shop you’re researching what their process is for handling customer orders. How transparent are they in this process? There’s more to running a machine shop than machining alone.

Whichever shop you choose should have a process laid out for how they intake, handle, and deliver your order. This shows you that they’re organized, and they’re thinking about your needs and deadlines.

What is their workforce like? Do you feel like they have enough people to complete your orders? Are the people on their team receptive?

In addition to how they handle their customers, they should also be providing you with prototypes or samples. Many shops don’t offer sample pieces, but these are very important if you’re doing a large scale production.

Failure to produce any samples or prototypes could cause you to be unhappy with the design, or even cause a slow down in the production process.

Reminders Before You Hire a CNC Machine Shop

In addition to what we’ve discussed above, there are a few things you’re going to want to consider before pulling the trigger on hiring a shop.

First, make sure to have an alternative material for your component. Sometimes the shop can’t get the material you were originally looking for, or it would raise production costs. Having an alternative in mind will help things to be more efficient.

Next, be specific. Express, in detail, what you want out of the machined parts the shop is making for you. Clearly communicating your precision and quality standards will go a long way in helping the project move along.

Finally, know how your product will be developed. If you’ve designed this part yourself, you need to consider how the product as a whole will be developed. If you design the part “in a vacuum” without considering how it relates to the project as a whole, you could be sent back to the drawing board a lot.

This will increase your production costs.

Final Cut

We’ve given you a lot of things to consider when you go to hire a CNC machine shop. Ultimately, all the research up-front will ensure a happy, efficient relationship on both sides.

If you take the time to properly vet and interview your potential machine shop, you could find one that will be a partner in your business for years to come.

If you’re looking for any more advice on machining, tools, or anything industrial, just check out our blog or drop us a line.

Aug 3, 2020 | MTM News

Can you imagine how boring life would be if you couldn’t rotate your arm, or your wrist didn’t tilt? Dance would be robotic, if not pathetic. Forget any kind of drawing or painting, you wouldn’t even be able to eat.

It’s no wonder that studies regarding the motion of human arms are still ongoing. This is an attempt to get machines to move as we do, for bionic application and more.

Articulation is not only beautiful, but essential to creating complexity. 5 axis machining takes those principles of rotation and tilt to new heights in fabricating a complex part.

In this introduction to 5 axis machining, we’re going to go over what it is, and why 3D printing won’t replace it.

5 Axis Machining: What Is It?

Imagine your XYZ coordinates from middle and high school for a moment. CNC machining uses an XYZ coordinate system we call the cartesian coordinate system. You can thank a French mathematician named René Descartes for inventing it.

the X, Y, and Z planes are 3 axis of motion left and right, up and down, and forward and back. In machining, the X and Y axes are horizontal, like you’re looking down at a tabletop. The Z-axis is the vertical axis.

The other two axes that 5 axis machining employs are rotation along an axis. These being the X and Y axes.

How Do the Axes Work?

Again, using your arm as an example, look at the back of your hand, and then rotate your hand over to look at your palm. You just performed a Y-axis rotation, so to speak, of 180-degrees.

Now flatten your hand and point your fingers to the floor, bending only at the wrist. Now point them to the ceiling like you’re saying “stop” with your hand. You just performed 180-degrees of rotation, this time on the x-axis.

5 axis machines are also called 3+2 machines because of the three positional axes, plus the 2 rotational ones. Some machines have more axes—don’t worry, we won’t get into that—but they offer little in increased part complexity or time reduction.

The only thing that more than 5 axes do is create more maintenance headaches, although there are needs in some industries for them.

The main takeaway is that a true 5 axis machine is better than a 3+2 machine, which only parodies the 5 axis concept.

Why Is 5 Axis Better?

True—or continuous 5 axis machining—as it is appropriately called, continuously adjusts the tool bit for the best angle to the workpiece.

Other systems, like 3+2, need the stationary toolbit to reposition. This extra process costs time and costs you money. 3+2 is still a good method, as it can always make the same product as a 5 axis machine in theory.

The benefits of 5 axis machining over 3 axis, positional, machining are:

- Design complexity

- Minimized setup

- Better surface finishes

- Quicker removal of material

- Rotational accuracy

When you can use shorter toolings you vibration and produce higher quality finishes, as well as minimal setup on the tooling. Arcs and angles that would before take several different setups allow a level of complexity that is unparalleled.

Shorter cutting surfaces enable higher speed with lower vibration, increasing material removal speed. Being closer to the workpiece makes all the difference.

These benefits are amazing, though it is not always necessary. You have to make a cost analysis to determine the need of 5-axis.

Avoiding Complications in 5 Axis Machining

Aside from doing a cost analysis, there are some other things you can do to minimize running into unnecessary complications.

First of all, only using tooling which is designed for a 5 axis machine will keep it in good working order. This will produce better results. 5 axis machines are costly, and keeping it in good working order will ensure fewer maintenance downtimes.

Hardware is super important, but also essential is the CAD/CAM software to process the cutting program without collisions. The best 5 axis machine in the world without a good cutting program and trained personnel is a 3 axis machine that can cause more problems.

In that vein, training your personnel to think about the machine’s capabilities is essential. All too often, 5 axis machines are limited by the imagination and creativity of the operators, rather than what is actually possible.

Simulation software is improving to take up the slack, though. It assists operators to reduce toolpath collisions and errors for smoother, faster operation. Cutting program simulations are essential on high-dollar items with exotic materials where you might only get one shot.

Done-In-One

It’s almost possible with 5 axis machining to perform done-in-one operations. This is a holy grail of the machine world, where multiple setups and staging aren’t necessary and all machining can be done in one operation. In goes a block of material and out comes your part.

More important than the machine in a done-in-one scenario is all in the planning, training, communication, and preparation involved. Making sure you have the right tooling and enough tools in the magazine to finish the job is essential.

5 axis fabrication won’t be replaced by 3D printing any time soon, but likely they’ll work together. Whether it be in a hybrid machine or where 3D printing does the rough-in while machining finishes the surfaces, both are here to stay.

5 Axis Machining: Now You Know

Speaking of done-in-one, it’s tough to talk about everything in 5 axis machining in one article but all the rough cuts have been made.

Before we finish, we wanted to invite you to our facilities and to read our other blogs on machining. Watching machining in action is like watching an elegant dance, as beautiful as a Rembrandt, and satisfying as a bite of homemade apple pie.

Thanks for reading so far and make sure to contact us for any machining information you might need!

Aug 3, 2020 | MTM News

Prototypes are a crucial part of the design process before full manufacturing can occur. They help to visualize what’s working and what’s not within a product.

Without a successful prototype, there is little chance that the product will be manufactured and sold. However, the first step in making a working prototype is finding a machine shop that can do the work for you.

There are many prototype machine shops around the world, but finding the right one can still be tricky. We’ve created the ultimate guide to finding the right shop for you.

Can Complete Your Manufacturing Project

First and foremost, you need to make sure that the large machine shops you’re looking into have the capabilities to create what you need.

There are all different types of milling machine options Each has unique capabilities and can only work within those. The operators of these machines will be able to work with you to decide if your project is possible with them or not.

Sometimes, a prototype may also need a few machines in order to be fully produced. In that case, finding a shop that has all of the right machines is even more critical.

You want the prototype development and production to move quickly and seamlessly. This will help you move on to production as fast as possible, which is the end goal. Making sure ahead of time that your piece can actually be produced in the shop eliminates many delays.

Clear Process Documenting System

The making of a prototype isn’t always a cut and dry process. It usually involves at least a few different steps and will likely take some time before it’s fully completed.

And, generally, you aren’t the person who is actually doing the producing. You likely won’t even be on-site during most, if any, of the process. That can be difficult to wait and see how things work out.

So working with a prototype machine shop that keeps detailed records as things are being produced can bring great peace of mind.

One way this is done is through a system where each piece is given a barcode that can be scanned and check up on at any time. Throughout the whole production process, you can see how things are going and what’s coming next.

Technicians Have Proper Training

Since you won’t be the person doing the actual manufacturing of your prototype, it’s really important to check out the credentials and training of the operators.

It’s likely that the operator will need to program the machines in order to get them to do exactly what you need. The operator will also need a healthy understanding of different materials, their strengths and weaknesses, and how to work with them correctly.

In this manufacturing process, the prototype machine operators become a very important resource and an asset to your success.

So you should really make sure the ones you choose to work with will be able to help you in any way you might need. That will look different for everyone, but having a clear understanding of what you need and then basing your choice on that is a good place to start.

Work in a Variety of Quantities and Materials

Obviously, not all prototypes are going to be the same. They aren’t all even in the same category. A prototype could be for any project, and the possibilities are literally endless.

So one of the most important steps in your design process is to figure out the best material to use.

Once you’ve figured that out, you’ll need to check with your shop to make sure their milling machine can work with that material. Not all machines or operators work well with all types of materials, so this is an important thing to check.

It’s also really important to make sure that you can get just one or 1,000 of what you need.

Different projects will require a different number of prototypes, so understanding what’s possible will help you plan better moving forward.

Fits Within Your Budget

Getting into product development can be an expensive venture. There are so many initial costs that go into a successful launch, from design to manufacturing to marketing to shipping. All of those things need to be worked into your budget.

Prototypes are a crucial element to a project but not the only element, so sometimes they get left out of budgets.

Getting an estimate for the cost of prototype production, and even a quote for a few scenarios, can help you better manage the funds you have. This will help you to understand how many you can get and how often you can try again for the right part.

Many shops are happy to lower cost for prototypes in hopes that you’ll choose them for full manufacturing, which can be a major boost to the overall budget.

Acceptable Turnaround Time

In the grand scheme of manufacturing and prototype production, the timeline isn’t often very quick. All of the steps take time for it all to come together.

But you don’t want that timeline to be extended longer than it needs to be, especially if you have other deadlines to meet within your overall project.

So it’s helpful to get an estimated time of completion and delivery before you begin working with any prototype machine shops.

The operators should be able to let you know what steps will need to be taken and approximately how long each one will be. This just helps you plan the whole project out more accurately.

Find the Right Prototype Machine Shops

Creating a new product is thrilling and exciting! It’s taking an idea you had and bringing it to life.

One of the most important parts of that process is working with prototype machine shops to get the product just right. These prototypes help you to tweak the product to be exactly what you have envisioned.

When you’re ready to get to work creating your prototype, contact us and we’ll be able to help you get started!

Aug 3, 2020 | MTM News

Are you wondering what 3 axis CNC machine systems are and how to use them? Do you want to know why the 3 axis option still stands strong even among higher multi-axis alternatives? Based on regional analysis, the competitive landscape for this machining system is intense, but because of the ease of use and sophisticated tool alternatives, it won’t be going anywhere anytime soon.

So what makes 3 axis machining so important? Why should you keep it in mind the next time you need to produce a high-end part for your business? Read on to learn about this powerful machining option and make the most of your local Wisconsin machine shops!

What is 3 Axis Machining?

So, what is 3 axis machining, and why might you need it? As the most used technique to create all kinds of parts, it’s crucial to understand how it works and how you could use it in your business.

The cutting tools move along three separated axes to mill the part you’re working on:

- Back-to-front

- Side-to-side

- Up-and-down

The cutting tools are held horizontally or vertically and spin while the piece you’re working on stays in place. You could use it to mill slots, flatten surfaces, drill, and tap holes, and cut sharp edges. Some of the benefits of 3 axis machining are:

- The three axes move together, which allows you more freedom to create complex components efficiently.

- This machine is the most versatile allowing you to produce fixtures, clamps, stocks, clamps, and more.

- If desired, these machines can have an automatic tool changer equipped, which will allow you to complete multiple objectives on one device.

- With additional coding, you can upgrade to a 3 axis CNC milling machine. The data only needs to be entered once for multiple uses. The 3 axis CNC machine definition gives the machine the ability to move three different axes at the same time simultaneously.

- Depending on your machining center, you can upgrade to more axes if needed, at an additional cost.

If you’re not sure how many axes or how complex your piece is, we can help you determine the right machine and offer you a quote, today!

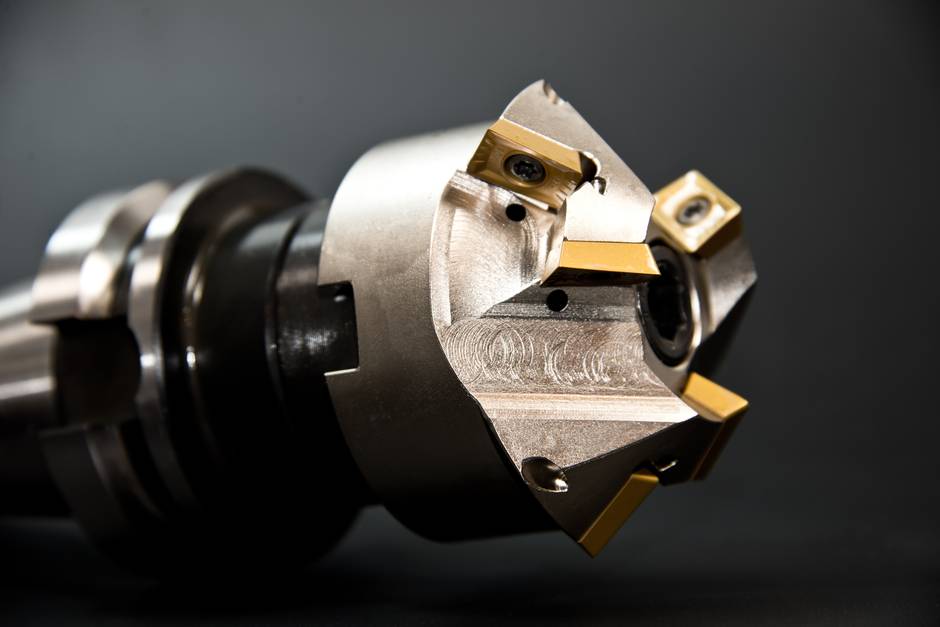

How Does 3 Axis Machining Work?

If you want to produce top-of-the-line parts, you need to utilize top-of-the-line machinery. If you want to gain and maintain your competitive edge, you should choose the tools you use carefully.

A milling machine works by shaving and cutting away the parts of your raw material that you don’t need. Multi-access milling and machining align the tool with your material and then works it down to your desired size and shape. The typical configuration moves the device while keeping your part stationary.

The tool moves along three axes: X, Y, and Z, or width, length, and depth. These axial movements through three dimensions involve two linear channels and a cutting head with a spindle. The spindle represents one axis as it works together with the width and length axes.

For the tool head, depending on if you’re cutting aluminum, steel, wood, etc., you can choose one that works accordingly. If you’re not sure what tool head to use, check this facility list to find a machining center near you where experts would be happy to help you solve that problem.

What is the Difference Between 3 Axis and 5 Axis Machining?

When it comes to choosing which machining needs suit you best, it can help to identify the main differences between the 3 and 5 axis options. But what other aspects of these options make them unique and which one serves your needs best?

Traditional 3 Axis Machining

While known for being the more rudimentary option, 3 axis machining has come a long way to become more modernized to keep up with the digitally controlled 5 axis alternative. The three axis option is most widely used to make mechanical parts in manufacturing, industrial work, and architecture.

The process uses the three main axes (X, Y, and Z) to shave down the material into the desired shape. This process isn’t ideal for deep or narrow parts because it’s limited on effectively reaching deep or narrow cavities on your material and may become more labor-intensive. As the industry demands new updates to keep up with the needs of users, 3+1 and 3+2 options bridge the gap to the five axis alternative.

Advanced 5 Axis Machining

Unlike the X, Y, Z, limitations of the 3 axis machine, the 5 axis moves in the three linear axes previously mentioned and the A and B axes, which means that your part can be manipulated from all directions in one operation of the machine.

This option is ideal for deeper parts, parts made with harder materials, and more precise because of it’s shorter tools. Additionally, if you’re short on time, the five axis option is faster than the three axis alternative.

Alternatively, the three axis machine handling is less complicated and requires less time to prep than the five axis. But, the digital controls make the five axis more user friendly.

Where to Start

Are you ready to locate your local, Wisconsin 3 axis machining facility and get to work? Start by identifying what you need, what cutting tool would work best, and what your intended result is for your project.

Whatever your machining needs may be, there is certainly an axis tool for the job! Additionally, if you need green energy, other heavy component machining jobs, food production, and more, let us know! When it comes to Wisconsin’s tool and machining jobs, we’ve got you covered!

If you’re not sure how to achieve your end goal, don’t be afraid to ask for guidance! Our philosophy is based on our desire to satisfy your needs, provide innovative performance tools, precision-based results, and technology on demand. For more information, fill out our form to contact us, and we will be in touch!